Pellet Pro Complete Upgrade Kit With Pid Controller Reviews

SHORT ANSWER: More than GRILLS HAVE PID NOW THAN EVER

PID controllers were in one case but on the most expensive and near technologically avant-garde pellet grills. But more and more grill manufacturers are using them now and many mid- to high-priced models use a PID controller. Manufacturers may still sell a few of their models with a conventional controller, much similar many auto manufacturers all the same produce some cars without cruise control, only several companies now outfit their models with some version of a PID controller. Before we detail which grills have PID controllers, allow'due south discuss the nuts of pellet grill temperature controllers.

| Make | Models w/PID Controller | Notes |

|---|---|---|

| Military camp Chef | Woodwind & SmokePro | |

| Green Mountain Grills | Almost all | Davy Crockett is not-PID |

| Grilla Grills | All, plus Alpha* | Alpha tin can switch from PID to time controlled |

| Memphis Grills | All | |

| Pit Boss | Platinum Series only | Others use conventional controller |

| Recteq | All | New Bullseye uses PID as well |

| Traeger | All, except Ranger/Tailgater | Traeger uses D2 Drive, with PID plus variable speed fans |

| Weber | Both pellet grills | |

| Z Grills | Unclear | Some listings claim PID, others simply refer to upgrade that fixes temperature issues |

PELLET GRILL TEMPERATURE CONTROLLERS: THE BRAINS

Constant Monitoring and Adjustments.

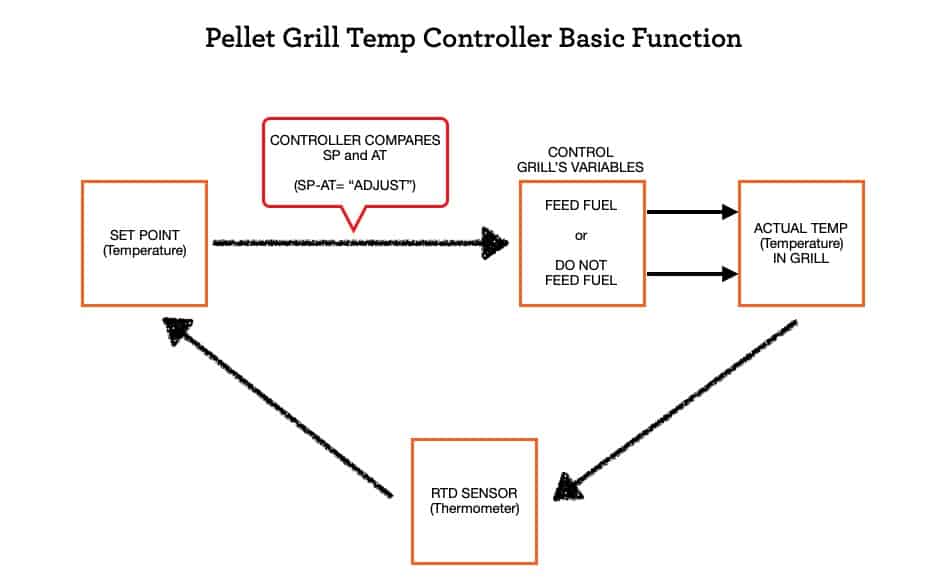

All temperature controllers in a pellet grill office in basically the same mode. You input a Set Signal (SP) which is your desired temperature. The controller is connected to a sensor inside the cooking bedroom, the RTD, which stands for Resistance Temperature Detector, simply think of it equally the thermometer in your grill. If the Actual Temperature (AT) as measured by the RTD is less than the Set Point, the controller controls the fuel system to heighten the temperature. It does this past turning on the auger, which delivers pellets to the fire, or by speeding up or slowing down the auger, which increases or decreases the rate at which pellets are fed in to the burn down. When the SP is reached, the controller either stops feeding fuel, or feeds at a rate to maintain that temperature.

Both PID controllers and conventional controllers operate on this basic principal. More woods = college temperature. No woods = lower temperature. The fans, past the way, are only the necessary secondary fuel for combustion. They kick on and off with the pellets, in order to maintain combustion and are usually not a factor in controlling temperature, but rather in maintaining the combustion of the pellets.

Because the heating procedure is being controlled by pellets entering the system, all pellet grills will feel some temperatures swings up and down. After pellets are fed into the fire pot via the auger, the burn down gets bigger. The temperature in the grill increases. Then the controller decreases fuel to the firepot and the temperature decreases.

The major divergence between a PID controller and a conventional controller is how that unavoidable temperature fluctuation is dealt with.

PID CONTROLLERS VS CONVENTIONAL CONTROLLERS

Conventional Controller: Auger On/Off is the Variable.

A conventional not-PID controller functions like your furnace in your business firm. You gear up a temperature. If the actual temp in the grill is lower than the setpoint, as measured by the RTD, a cycle is started to begin rotating the auger, which feeds pellets into the fire pot. If the temp in the grill is higher than the setpoint, a different cycle is begun which doesn't feed pellets to increase the temp, but feeds plenty so that the burn doesn't go out. There is a "college than wanted" wheel and a "lower than wanted" cycle. The fan kicks on and off with these cycles in guild to support the combustion needs (air) of the fuel.

Side Annotation: The info here can get a get bogged downwards in technical particular. Feel free to skim. Pit Dominate has a very straightforward explanation of PID controllers in pellet grills on its site, though they don't actually explicate HOW they work, just the benefits of having one. Continue reading to learn about the how.

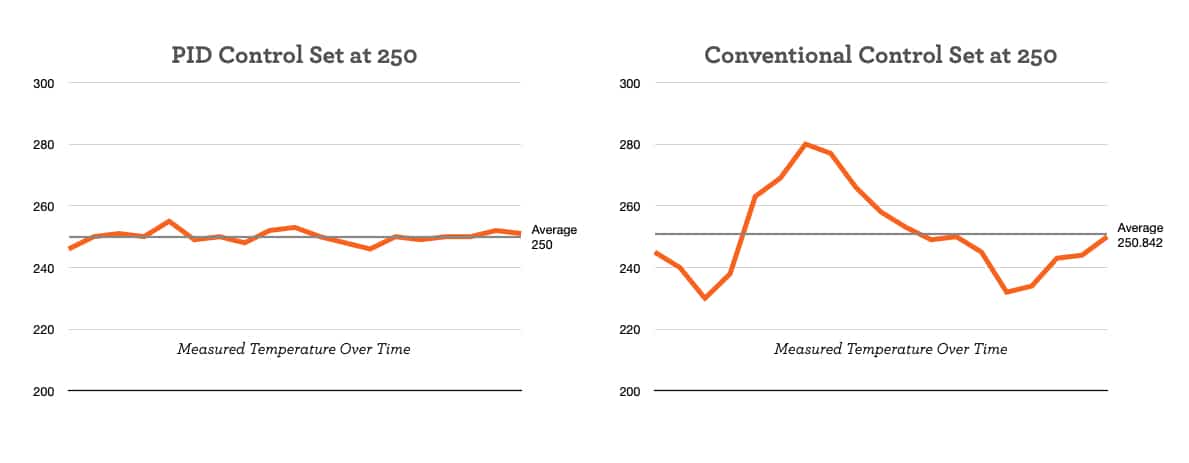

With this method, the grill is able to maintain a temp adequately shut to the Set Point, peculiarly averaged over time. The grill will, however, become through temperature swings equally it continuously overshoots and undershoots the Set Indicate goal. The swings might be 10, xx or even 50 degrees. Over the length of a melt, especially a longer cook, it all averages out. Conventional controllers, and so, maintain a correct average temperature that is effective.

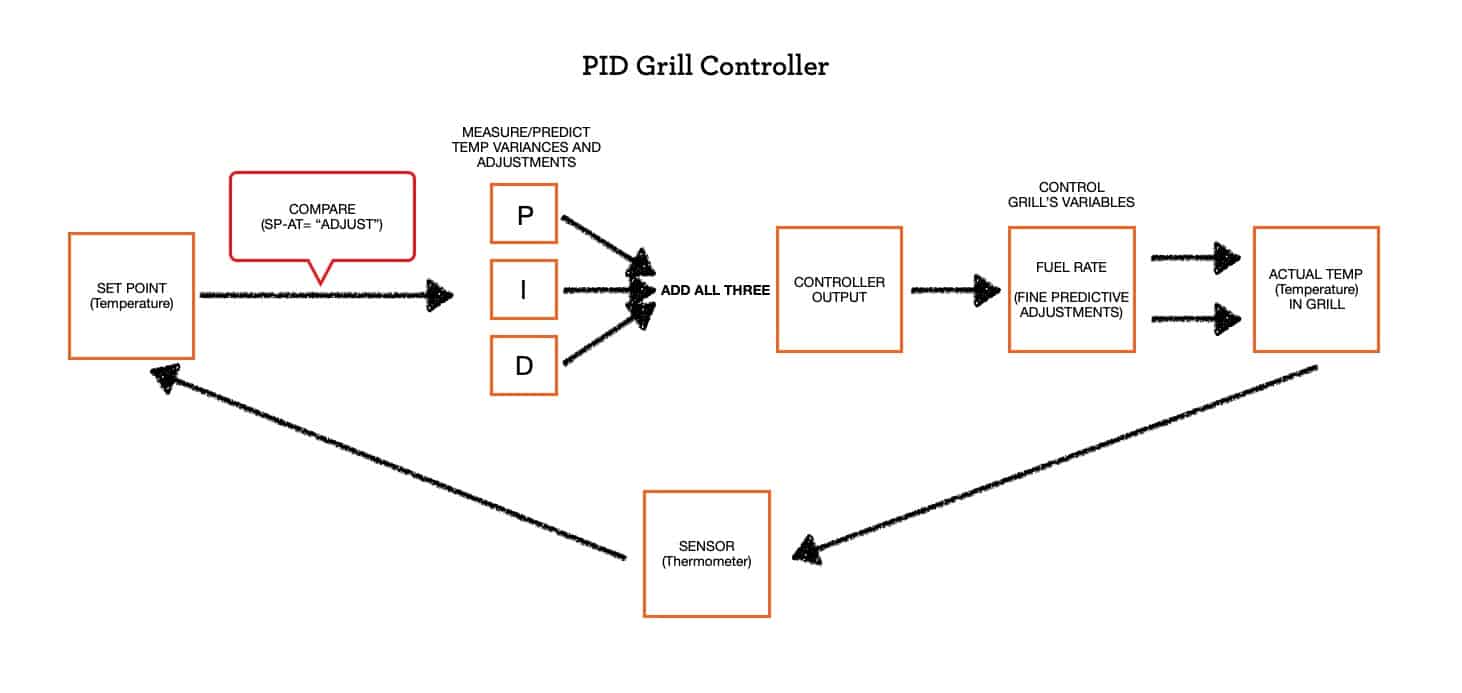

PID Controller: Everything is Sampled More Frequently, and Predictions are Fabricated

PID stands for Proportion, Integral and Derivative. These are three separate calculations used in maintaining a Ready Betoken that are more advanced than only a cycle for too-depression temperature and a bike for also-high temperature. To simplify things, think of a conventional controller every bit using addition and subtraction, and a PID controller equally using algebra and calculus.

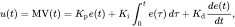

You might want to skip this department. It'south complicated. And that's the point. A PID controller uses algorithms effectually its sampling with three methods. PID controllers are used in industrial processes to control temperatures, fluid menses, air pressures, etc. Just to impress yous with some fancy looking math, here is the formula used to derive the amount of a manipulated variable (MV) (fuel feed rate) needed, when computing the P (Kp), I(Ki) and D(Kd) inputs:

The Proportion part of the PID in a pellet grill is the PROPORTION of fourth dimension on/off of the auger, based on needed temperature adjustments.

The INTEGRAL role controls how ofttimes the temperature is measured over a flow of time, in order to get a more authentic spread of readings (temperatures from the RTD.)

The DERIVATIVE part is the real magic. It basically predicts the changes that will occur as well as how fast they'll occur, to fifty-fifty more accurately control the temperature changes.

The in a higher place is a serious simplification of the process. The bottom line is that temperatures are maintained more accurately with a PID controller than with a conventional controller, because it is sampling more often and doing more adjustments and even predictions based on that info. What results is a more steady temp, without overshooting or undershooting the Set Point.

-

Rec Tec/recteq PID Controller -

The "guts" in a PID controller

PID Controllers vs Conventional Controllers: When it Matters Nearly

A conventional controller volition maintain a steady 350 degrees over 30 minutes. It may swing a bit upwards and downward, but it'due south basically going to cook at an average of 350 degrees. This is fine. Your oven does this. Your furnace does this.

Where a PID controller really has advantages is when more variables occur that affect the grill's temperature. These variables can include:

- Outside ambient temperature

- Wind

- Pelting/Snow

- Beginning food temperature

As an example, take a pellet grill with a conventional controller set to 350 on a 45 degree day. That controller was programmed with a bike to get to 350 and to maintain 350. It was likely set to do it when the outside temp is 75 degrees. So at present it's going to run that cycle. Only considering of the outside temperature, it won't achieve 350.

Then, information technology kicks in the "temp too depression" cycle to conform. The temp may now shoot to 370 or 380. Now the "temp also high" cycle kicks in. And the temp falls manner faster than normal, because of the cold outside air. And so information technology may plummet to 300, which kicks in the "temp likewise low" cycle again. Like scenarios play out with very hot days/direct sunday, high winds, rain, or when you put on a 10-lb Boston butt straight out of the fridge. The grill is in a constant state of trying to adjust. But its adjustments are rough, causing wild swings in temps.

A PID controller, even so, is predictive, as it'southward learning from how long information technology'south taking to adjust and applying that learning to its adjustments. It is able to more finely and accurately keep that temp at 350.

The issue? Both foods volition cook. Ane will cook at a range of 345-355. The other may hit lows of 300 and highs of 400, depending upon conditions. Not a huge bargain, merely it could crusade cooks to be more than unpredictable so that your recipe tastes differently in July than in November.

SOME Prefer CONVENTIONAL TO PID CONTROLLERS

Some people say that a conventional controller will accept more than smoke, as lower temps produce more smoke. And so when a grill swings down to 300 from 350, it's producing more smoke (at to the lowest degree temporarily). I would counter that it'due south also producing less fume when it overshoots to 390 than it was at 350.

Bottom Line

The aphorism in smoking is that the key factors in predictable results are temperature and time. Consistencies in both produce great results. Conventional controllers produce fairly consistent temperatures. PID controllers produce MORE consistent temperatures, especially in less-than-perfect weather condition.

Whatever pellet grill will cook tastier food, with more than consistent results, than a propane grill (what most people accept.) If a PID controller isn't in your current grill, or if it's not in your budget for a new grill, don't worry. It still works. But a PID controller is just an even more than accurate way to finely control your cooks.

Source: https://pelletgrillreviews.com/pid-controllers-in-pellet-grills/

0 Response to "Pellet Pro Complete Upgrade Kit With Pid Controller Reviews"

Post a Comment